About the Project

ALGALUTION develops algae-based bioplastics that perform like conventional plastics but naturally break down within months. The project focuses on creating scalable, affordable alternatives suited for everyday use, starting with takeaway bags. By combining locally sourced algae and natural starches, ALGALUTION aims to reduce plastic waste and promote responsible consumption across Southeast Asia through science-backed innovation.

Why do you care about this specific topic/issue?

We’ve always been aware of the growing plastic problem, but what pushed us to take action was how often the so-called “solutions” felt shallow. From charging extra for plastic bags to labeling products as “eco-friendly,” too often these efforts seemed more like marketing than meaningful change.

With backgrounds spanning computer science, environmental management, and economics, we began asking some questions: Why do we still rely on the same materials? Why are alternatives so limited or expensive? The more we dug in, the clearer it became that much of the plastic conversation focuses on managing symptoms rather than addressing the root cause. That mix of frustration and a deep sense of responsibility for the future drives everything we do.

Why did you decide to start this project?

We began with a simple but powerful question: what if we didn’t just manage plastic waste, but eliminated the need for conventional plastic altogether? This question felt especially urgent in Southeast Asia, where mismanaged plastic waste leads to an estimated $6 billion in economic losses every year.

That’s when algae caught our attention. It’s abundant, underutilized, and incredibly versatile. We realized it could be transformed into a material that performs like plastic but breaks down naturally.

At ALGALUTION, we’re driven by the goal of creating alternatives that make sense both environmentally and economically. We’re developing a scalable, affordable solution rooted in local production – one that communities and industries can realistically adopt and benefit from.

What are your goals for this project?

Our goal is to develop algae-based bioplastics that can realistically compete with conventional plastics—affordable to produce, reliable to use, and scalable across markets. We’re building a localized algae cultivation system and refining our formula with natural starches to ensure both performance and cost-efficiency.

In the long term, we aim to expand throughout Southeast Asia, supported by ongoing research and development as well as strong partnerships to transform this material innovation into a commercially viable alternative embraced by industries and institutions.

How will YSEALI Seeds help you achieve your goals?

The support from YSEALI Seeds for the Future has been crucial in moving ALGALUTION forward. For a pioneering project like ours, starting from scratch, securing initial backing can be a major challenge. The grant has provided us not only with vital financial resources but also with the confidence to turn our vision into reality.

Beyond funding, YSEALI Seeds for the Future’s support acts as a strong validation that our innovative idea is impactful and worth pursuing. This encouragement directly empowers us to achieve our ambitious goals of developing and scaling algae-based bioplastics for a better future.

What have you accomplished and implemented so far?

We’re currently in the foundational phase of ALGALUTION, focusing heavily on research and development. We’ve been actively engaging with various academic and research institutions to deepen our understanding of the product and explore opportunities for collaboration, including potential access to laboratory facilities.

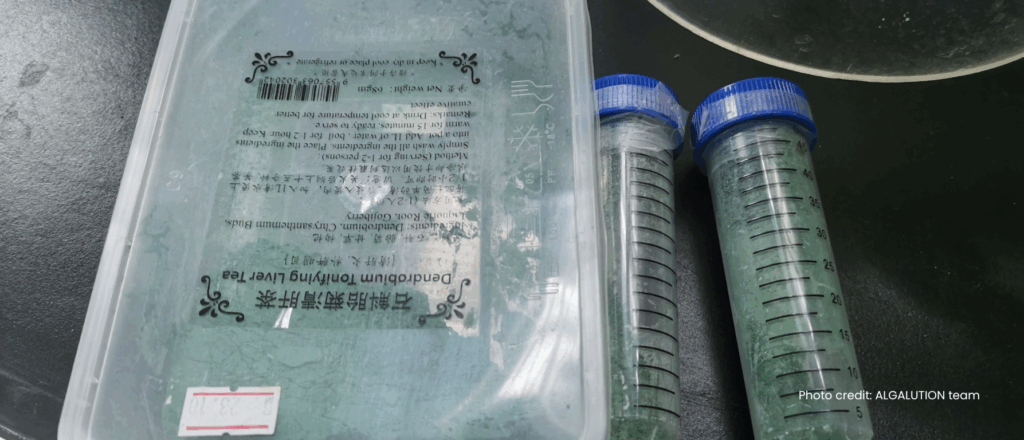

Through collaborative research and stakeholder input, we’ve identified the potential to use locally abundant starches combined with algae lipids to create a promising bioplastic formula. This combination is known to improve polymerization, stability, and durability, while keeping production costs manageable. While we have strong indications from existing studies and early consultations, laboratory testing and pilot production are upcoming steps to validate and refine the formula.

Our R&D efforts aim to develop a material that meets performance standards like strength, flexibility, and biodegradability, paving the way for a scalable and economically viable solution across Southeast Asia.

What are the most significant lessons learned you’ve experienced so far?

One big lesson we’ve learned is that innovation isn’t always about starting from scratch. More often, it’s a subtle, almost magical process where you gather a wide range of information, ideas, and feedback over time. It requires patience and openness to see how these pieces connect, sometimes in unexpected ways.

Through this process, the real solution gradually comes into focus not as a sudden breakthrough, but as the result of thoughtful iteration and collaboration. We’ve found that the most effective innovations often come from reexamining and refining existing methods rather than completely reinventing them. This mindset encourages us to build on proven knowledge and resources, allowing us to develop practical, scalable solutions that can make a real difference.

What are the success stories you can share with others?

Amidst the challenges we’ve faced, we have also achieved meaningful breakthroughs. Our collaborations with researchers and potential partners have been transformative, uncovering the untapped potential of locally sourced raw materials an opportunity we had initially overlooked. This insight now stands as a cornerstone in our pursuit of a cost-effective solution.

Our deep dive into existing research revealed the vital role of starch in bioplastic production, guiding us to harness Malaysia’s abundant corn and tapioca resources. These natural elements are more than just ingredients; they form the foundation that imparts strength, flexibility, and resilience to our bioplastic.

Despite limited resources, our unwavering commitment to rigorous research and community collaboration has established a solid foundation. We are now ready to further refine our formulation and confidently advance toward pilot production, taking concrete steps to address the urgent plastic waste crisis across Southeast Asia.